Tooling Excellence

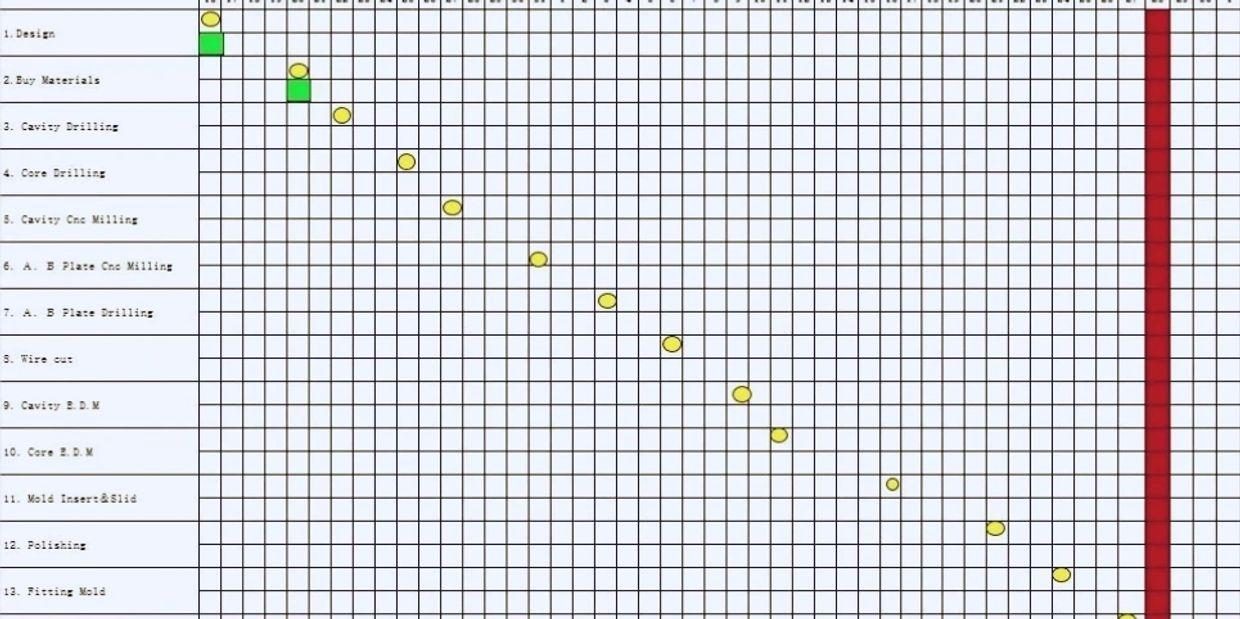

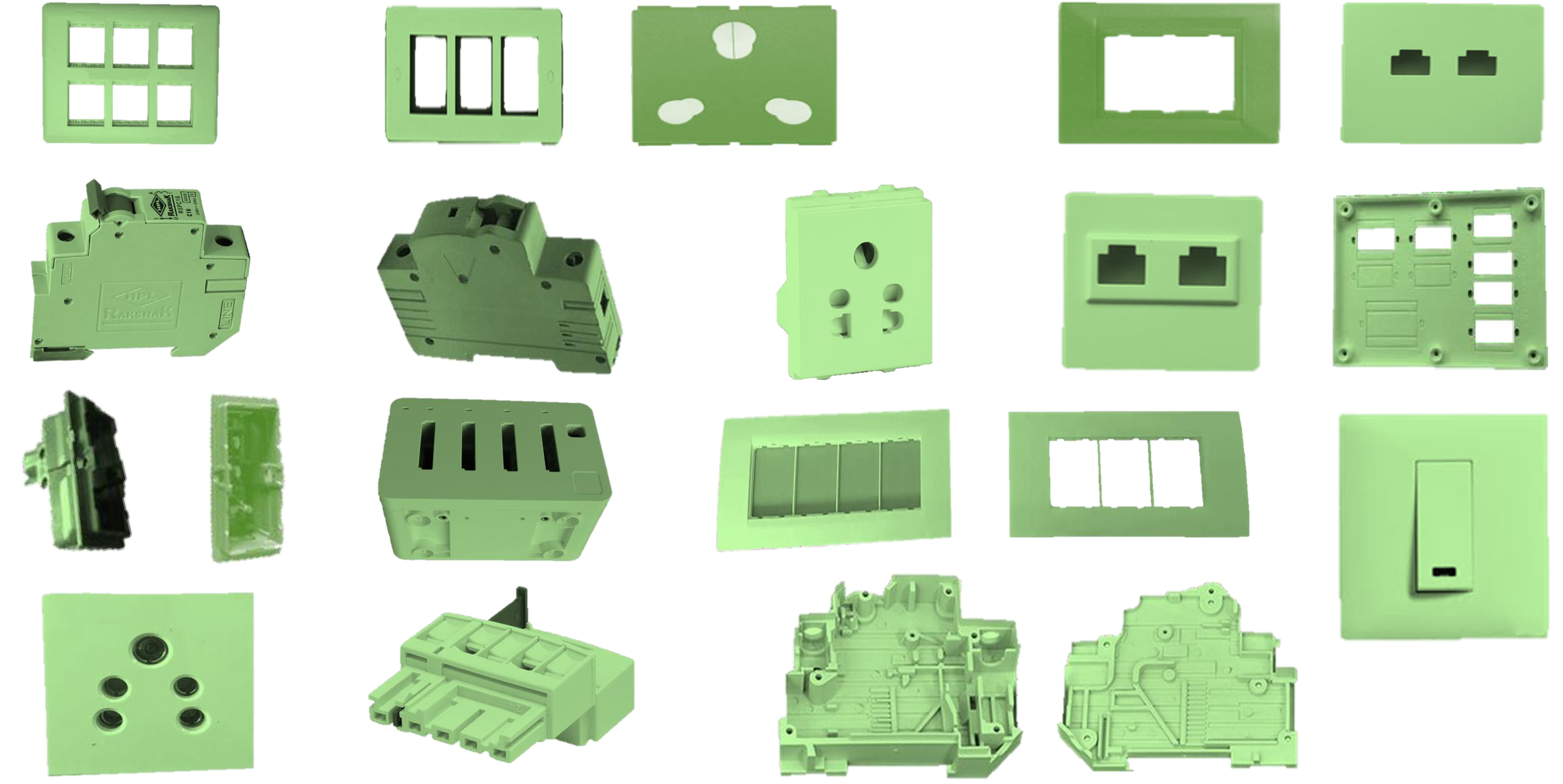

At IB Molds tool design and manufacturing process involves several steps that ensure the efficient and accurate production of tools. Here are the basic steps involved in this process:

1. Define the requirements:

The first step is to determine the purpose of the tool, including the materials it will work with and the intended usage. This will help in determining the design requirements.

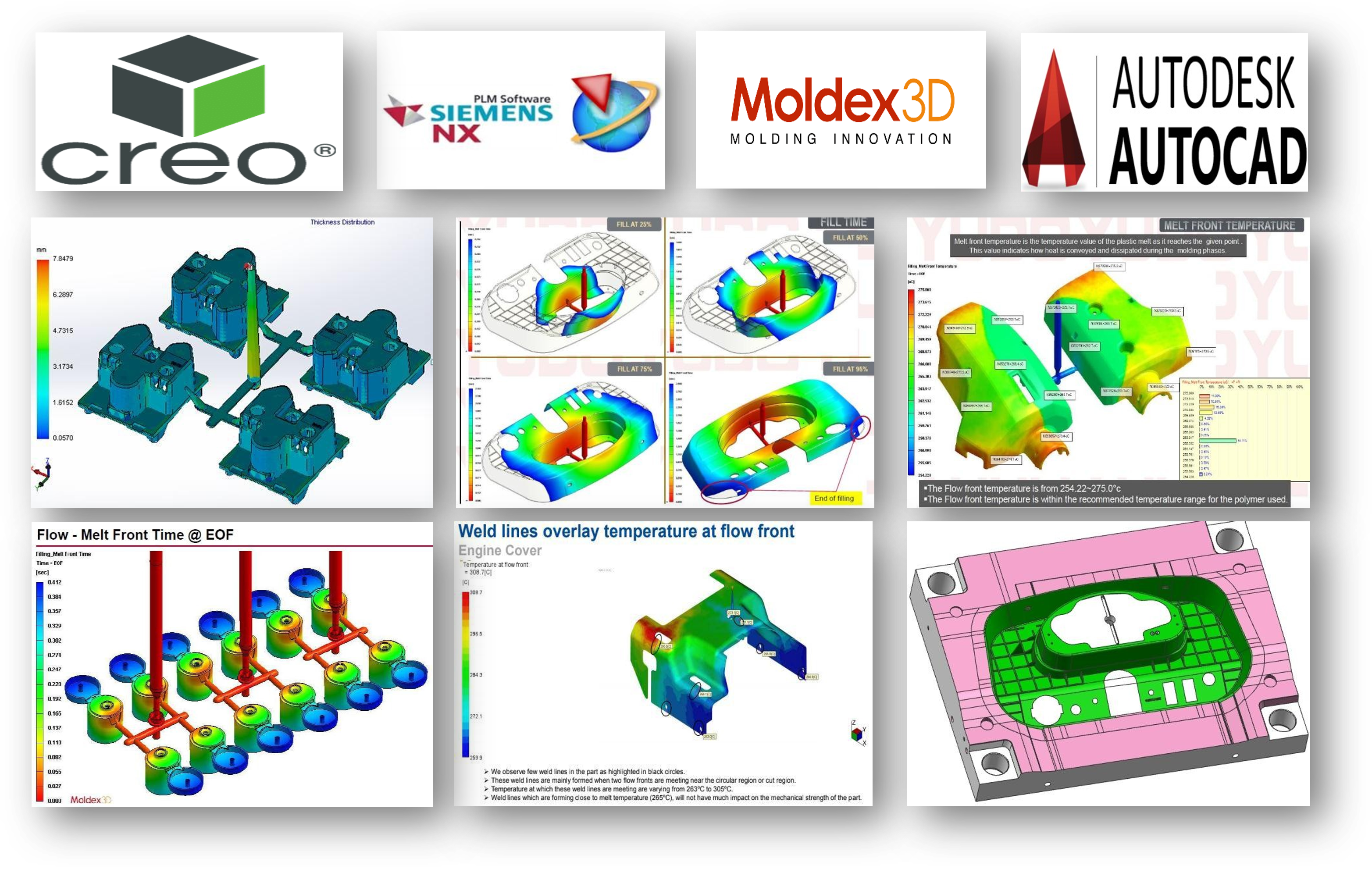

2. Design the tool:

Once the requirements are defined, the tool can be designed using computer-aided design (CAD) software. The design must meet the specifications and requirements set in step one.

3. Create a prototype:

A prototype of the tool is then created to ensure that the design works as intended. This step involves testing the prototype to ensure that it performs as expected.

4. Manufacture the tool:

Once the prototype has been approved, the tool can be manufactured. The manufacturing process involves several steps such as material selection, machining, heat treatment, and finishing.

5. Quality control:

Throughout the manufacturing process, quality control checks are carried out to ensure that the tool meets the required specifications and standards.

6. Assembly and packaging:

The tool is then assembled and packaged according to the manufacturer's requirements.

7. Delivery:

The finished tool is delivered to the customer, along with any necessary documentation, instructions, and warranties.

Overall, IB Molds tool design and manufacturing process goes through careful planning, attention to detail, and rigorous quality control to ensure that the final product meets the desired specifications and standards.